the fundamentals of hardness testing|hardness tester for thin material : Brand manufacturer Hardness testing is perhaps the simplest and the least expensive method of . webWindguru weather forecast for Brazil - Santos. Special wind and weather forecast for windsurfing, kitesurfing and other wind related sports.

{plog:ftitle_list}

If the cache server already has a copy of the requested data, .

This chapter discusses the history of hardness testing and defines the term hardness. It describes the interrelationship between material structure and hardness and the relationships between hardness and other mechanical material properties.The principal purpose of the hardness test is to determine the suitability of a .Hardness testing is perhaps the simplest and the least expensive method of .

The principal purpose of the hardness test is to determine the suitability of a material for a given application, or the particular treatment to which the material has been subjected. The ease .

Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been . Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well .

This publication provides, based on the state of standardization, an overview of the hardness testing of metals, plastics, rubber and other materials.

Hardness testing is perhaps the simplest and the least expensive method of mechanically characterizing a material. This article provides an overview of the principles of hardness testing.Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been developed to measure it. This chapter discusses the history of hardness testing and defines the term hardness. It describes the interrelationship between material structure and hardness and the .

Contents. Chapter 1 The Fundamentals of Hardness Testing. 1. Chapter 2 Hardness Measurement of Metals Static Methods. 25. Chapter 3 Dynamic Test Methods. 67. Chapter 4 .Around 1900, Martens proposed the following definition for hardness testing: “Hardness is the resistance of a body to the indentation by another (harder) body.” This simple but precise definition has taken its place in technical . The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness

Hardness testing is a fundamental material science technique that measures a material’s ability to resist deformation. It is an essential parameter in the manufacturing industry, as the hardness of a material can . Hardness is not a fundamental material property, so it should be viewed in context with other properties such as strength, elasticity and ductility to understand how these properties relate to each other. For example, while a .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The . DOE Fundamentals Handbook, Volume 1 and 2. January 1993. U.S. Department of Energy, Material Science. DOE Fundamentals Handbook, Volume 2 and 2. January 1993.

This chapter discusses the history of hardness testing and defines the term hardness. It describes the interrelationship between material structure and hardness and the relationships between hardness and other mechanical material properties. . {The Fundamentals of Hardness Testing}, author={Katrin Herrmann}, journal={Hardness .Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the permanent depth of the indentation. More simply put, when using a fixed force (load) and a given indenter, the smaller the indentation, the harder the material. . The Rockwell .

Mohs Hardness Test: This qualitative test ranks minerals based on their scratch resistance against standard materials with known hardness values. It’s commonly used in geology and mineralogy for mineral identification. These hardness testing methods serve various purposes, from quality control in manufacturing processes to material selection .Fundamentals of Hardness Testing of Fasteners. no.201/2023 275 an indentation invisible to the naked eye. These are referred to as micro hardness tests. For general purpose testing, macro hardness testing is what is usually employed. There are multiple different test methodsHardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the permanent depth of the indentation. . Hardness testing is used for two general characterizations Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).

The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test force >= 49.03 N), more precisely with a test force of 29.42 to 1471 N. It is a differential-depth method.This chapter explains how metallography and hardness testing are used to evaluate the quality and condition of metal products. It also discusses the use of tensile testing, fracture toughness and impact testing, fatigue testing, and nondestructive test methods including ultrasonic, x-ray, and eddy current testing. . The Fundamentals of .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The . DOE Fundamentals Handbook, Volume 1 and 2. January 1993. U.S. Department of Energy, Material Science. DOE Fundamentals Handbook, Volume 2 and 2. January 1993.

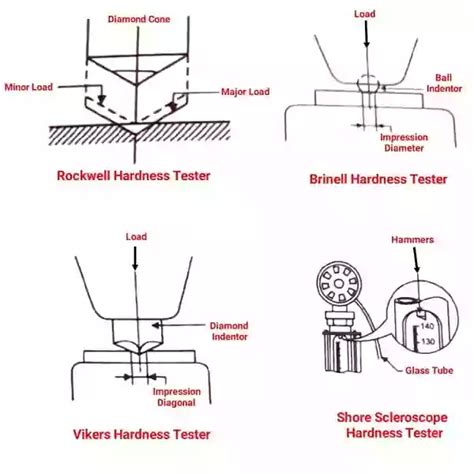

Fundamentals of Rockwell hardness testing - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The Rockwell test is a measure of the resistance of material, specifically metals, to permanent indentation. Indentation hardness is not a fundamental property of a material. The Rockwell test is covered by ASTM test method e 18.Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the resistance of material, specifically metals, to permanent indentation. Indentation hardness is not a fundamental property of a . Although the most widely used hardness test methods for metals—Rockwell, Brinell, and Vickers—were developed between 1900 and 1925, numerous technical innovations have been made in recent years, leading to .

Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been developed to measure it.Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). . DOE Fundamentals Handbook .

It compares Brinell with Meyer hardness testing and hardness testing of fully cold worked metals with fully annealed metals. The article discusses the plastic deformation of ideal plastic metals under an indenter, by a flat punch, and by spherical indenters. . The Fundamentals of Hardness Testing. Hardness Testing Principles and Applications .The Fundamentals Of Hardness Testing In Aerospace Engineering. At the confluence of physics and engineering, hardness testing is a cornerstone of aerospace innovation. The process is foundational for determining a material’s suitability for the demanding conditions of flight. Here are the fundamentals of hardness testing in aerospace engineering: Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the . Hardness testing is one of the most popular, reliable and yet diversified material testing methods. Most hardness testing is performed by using the Rockwell, Brinell or Vickers method. . Lean Manufacturing and Service Fundamentals, Applications, and Case Studies. See More Products. Recommended Articles. Meet the 2024 Quality Rookie of the .

Fundamentals of hydrogen embrittlement in steel fasteners S. Brahimi to failat stresses that are significantly lower than the basic strength of the fastener as determined by a standard tensile test. Theoretical models that describe hydrogen damage mechanisms under idealized conditions have been proposed since the 1960’s. Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for the Mohs scale do not have a graded increase, the Mohs scale lacks accuracy and is only a rough measure of hardness. .Hardness tests provide valuable information about the quality of materials and how they are likely to perform in different types of service. This chapter covers some of the most widely used hardness testing methods, including Vickers, Rockwell, and Brinell tests, Shore scleroscope and Equotip hardness tests, and microindentation tests.

types of hardness testing methods

Hardness testing technology remained fairly consistent throughout the mid to latter 1900s, most systems typically utilizing the dead weight method of applying the test forces. . Lean Manufacturing and Service Fundamentals, Applications, and Case Studies. See More Products. Recommended Articles. Meet the 2024 Quality Rookie of the Year: Justin . The hardness of a material is the property that enables it to resist deformation, bending, scratching, abrasion, or cutting. If you work in materials manufacturing, you probably already know that a hardness test is a crucial step in the production process for your products and the products you receive from third-party suppliers.

types of hardness testing machine

hardness testing techniques

WEBThe Killing: Created by Veena Sud. With Mireille Enos, Joel Kinnaman, Billy Campbell, Liam James. A police investigation, the saga of a grieving family, and a Seattle mayoral campaign all interlock after the body of 17-year-old Rosie Larsen is found in .

the fundamentals of hardness testing|hardness tester for thin material